WEEK-5 (FEB- 26.02.2020)- 3D Scanning and Printing

ASSIGNMENT-

The scope of the group assignment was to characterize and formation of design rules for 3D printers. The 3D printer available at our FAB Lab is Sindoh- 3DWOX. Each member of the group has played their part during the group assignment process.

3D printer used:-

Sindoh 3DWOX (181)- The lab is having 3 printers of Sindoh 3D WOX. I have used one of it to charaterise the 3D design rules of each printer of same make may also vary which we have noticed in our charaterisation.

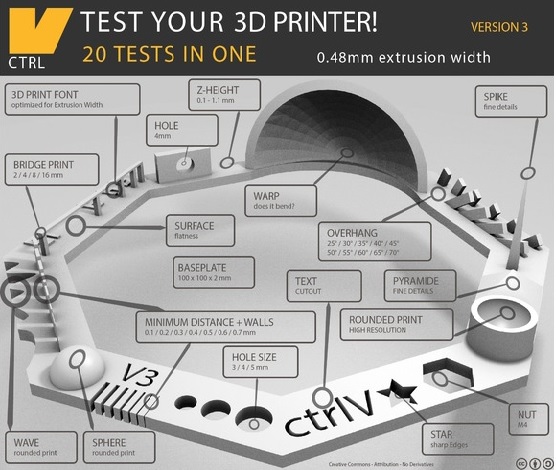

Test design:-

The above test design was downloaded from .https://www.thingiverse.com/ . The design has many parameters against which our 3D test rules can be formulated.

[*Note:- As the lab has 3 nos. of 3D printers of the same make we have done characterisation on each and to identify each printer the last 3 digits of the serial nuber has been used]

Observations and test rules for the design in Sindoh 3DWOX (181)-

Following parameters were available in the test design:-

01) Nut, Size M4 Nut should fit perfectly

02) Wave, rounded print

03) Star, Sharp Edges

04) Name, Complex Shapes

05) Holes, Size 3, 4, 5 mm

06) minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

07) Z height: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm

08) Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

09) Bridge Print: 2, 4, 8, 16 mm

10) Sphere, Rounded Print 4.8mm height

11) Sphere Mix, 7 mm height

12) Pyramide, 7 mm height

13) Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°

14) Warp, does it bend?

15) 3D Print Font, optimized for 3D printing

16) Surface, Flatness

17) Size, 100 x 100mm x 23.83 (10mm width)

18) Spike, minimum Layer Time, 21 mm height from Bottom (include Baseplate)

19) Hole in Wall, 4 mm diameter, check for proper print

20) Raft Test, raft should be just under the model

21) Retract Travel, check retract settings for longer travel

I have highlighted the basic outcome of unsuccessful 3D prints:-

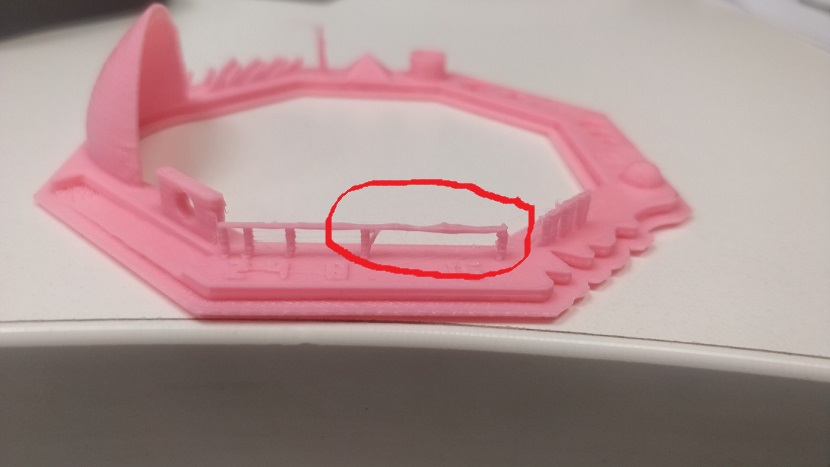

1) Bridge Print-

The parameters for providing support in the Bridge print was at distance of 2 mm, 4mm, 8mm and 16mm. The printer printed well for 2, 4 and 6 mm but the print was not clear at a distance of 16 mm without providing support in between.

The out come of the print was acceptable but not with accuracy. The 3 D print was done properly for 2, 4 and 6mm but accurate printing was not done at a dsitance of 16 mm without support. However the result was better than our other printer Sindoh 3DWOX(180).

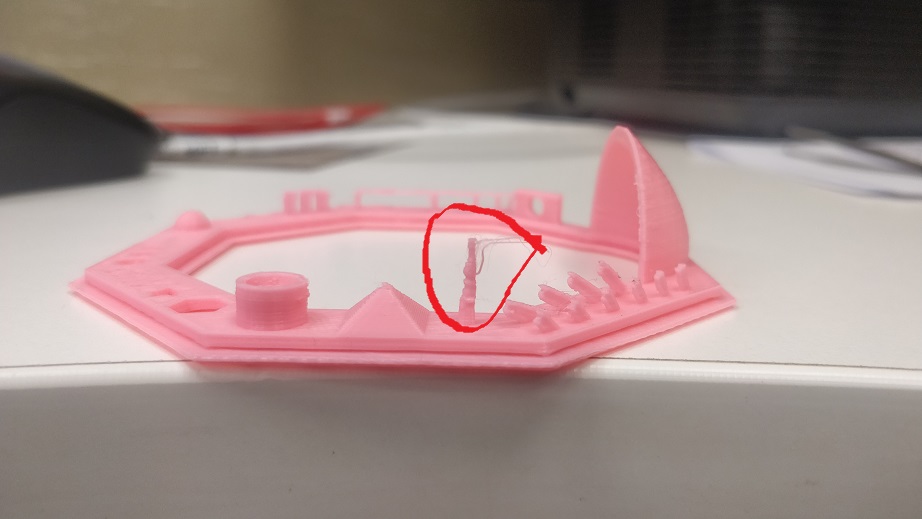

2. Spike Printing:- The criteria for spike was minimum Layer Time, 21 mm height from Bottom (include Baseplate).

The result we got in our 3D print was not good. The spike was having a height of only 10.5 mm. The rest of the part was not printed by the printer. However the spike was good as compared to our other printer Sindoh 3DWOX(180). The image of the spike printed is as under:-

3. Over Hang:-

This parameter was tested for various angles i.e. 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°.

The result for each angle tested was satisfactory. The 3D print was very strong and hence the printer can be very well used for printing all the angles as mentioned above. With comparision to our other printer which is Sindoh 3DWOX(180) the printing at angle of 45 degree was not satisfactory and the PLA deposition on this angle was not strong enough to be durable. The image of the Over Hang from Sindoh 3DWOX(181) is shown below:-

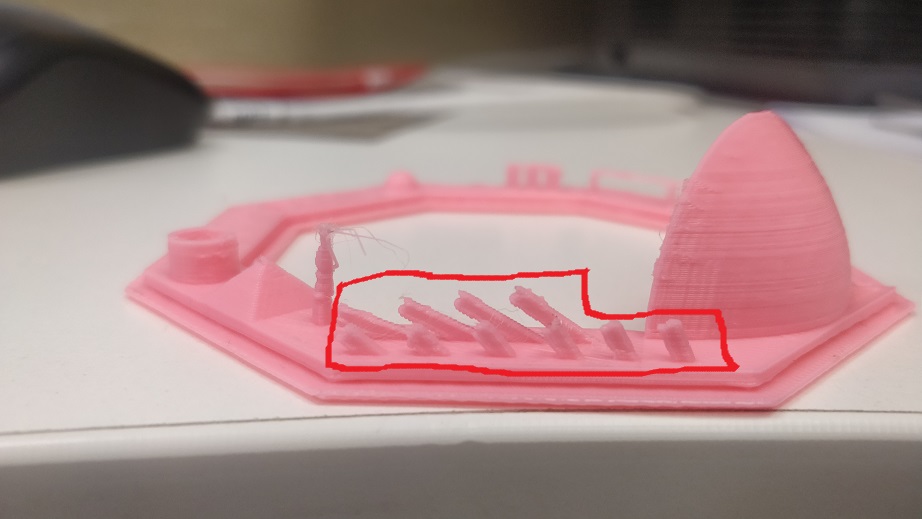

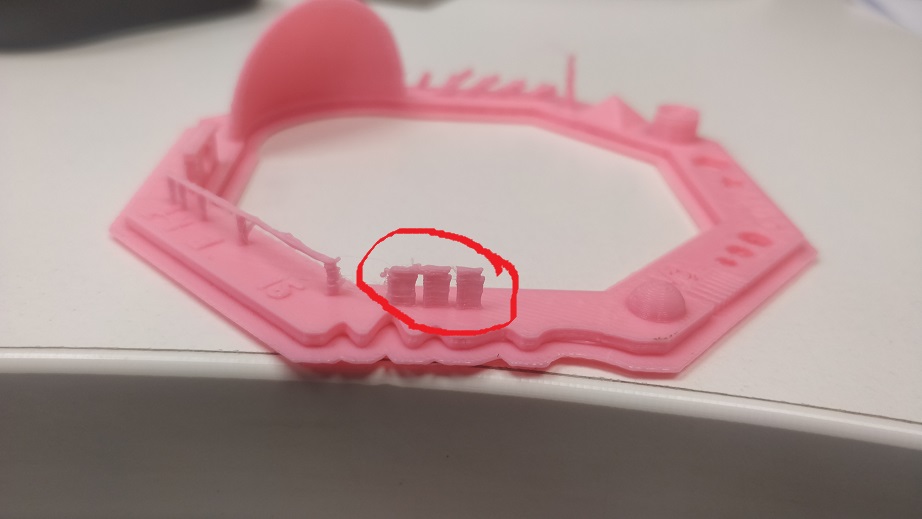

4. Wall Thickness:-

The thickness of the wall was measured for 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm.

The result of printing was not up to the mark. The 3D print was done only for 3 walls and for rest of the walls, the 3 D printer did not print anything. As per the print received, the 3 D printer printed the dimensions of 0.65 mm, 0.80 mm and 1 mm. The other dimensions of the walls were not printed. The images of the wall printed on the 3D printer is as under:-

The observations found in comparing the two 3D printers of same make and model is that there may be diffrences in the prints of the same printer as well. In our case Sindoh 3DWOX (181) has better printing capability than Sindoh 3DWOX (180).